Touch Screen Integration & Display Services

In addition to our touch screen product line, Dignity also offers touch screen integration services to our customers. Touch screen integration bonds the touch panel and sensor to the selected display in order to fix it in place for final integration into a metal or plastic enclosure. Integration can offer a wide range of benefits, but there are a number of considerations based on enclosure design, end application, LCD structure, etc. A consultation with Dignity’s experienced project team can help you determine the right solution for your needs and then put that solution in place.

• ISO 9001 and 14001 certified manufacturer with class 1K clean room and class 100+ integration areas

• Flexible production cells to improve process control and reduce MOQs

• Turn-key solution reduces supply chain and logistics costs

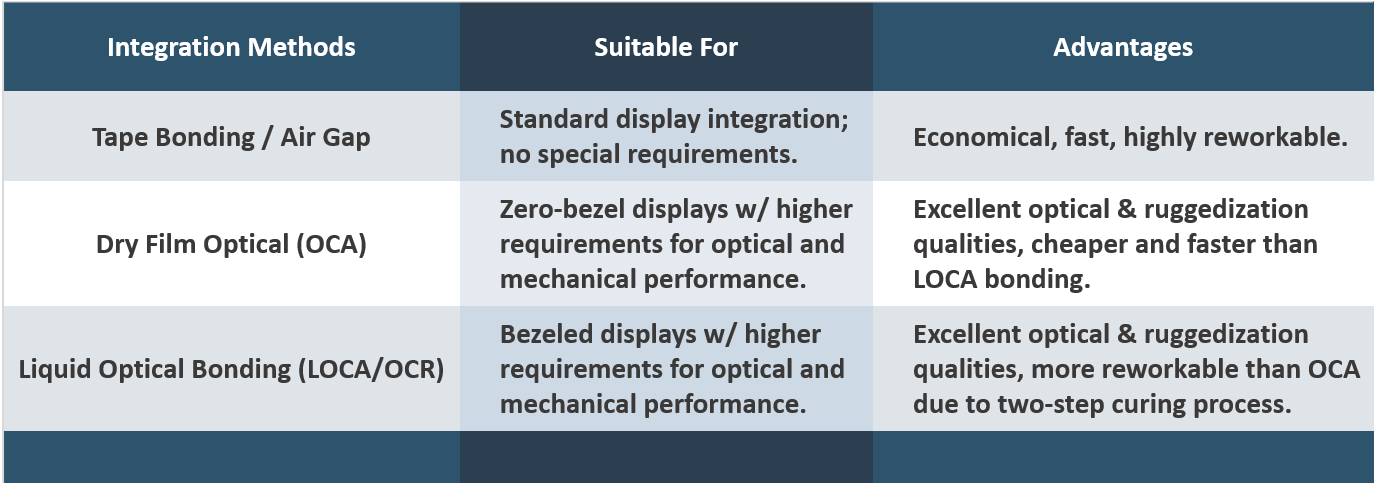

Dignity offers the following options for touch screen and display integration:

Tape Bonding

Also known as air gap or perimeter bonding, this is the simplest and most economical way of adhering the touch panel to the display. This process takes place in our cleanroom where we use a variety of industrial adhesive tapes and specialized jigs/positioning frames to assist the process.

• Cost effective solution to provide improved mechanical and environmental performance at low costs

• Extremely high yield rate and high reworkability

Dry Optical Bonding (OCA)

Dry optical bonding uses sheets of clear sheet adhesive to completely fill the air gap between the display and touch panel and enhance the performance of the assembly. A good mix of improved performance, efficiency and cost competitiveness.

• Cost is considerably lower than LOCA, with good performance for most applications

• Fast and easy integration process using pre-cut sheet adhesive

• Similar optical and mechanical qualities to LOCA bonding

Liquid Optical Bonding (LOCA)

Liquid optical bonding (or LOCA) is a bonding method where the touch sensor is adhered directly to the display by using an optically clear adhesive to form a direct bond without leaving any gap or space between the two. It is generally the most expensive bonding option and is often used for the most demanding or exacting environments, where performance is at a premium.

• Superior optical qualities including better contrast, better transmission, better readability and other aspects by removing internal reflections between the display and the touch assembly.

• Superior mechanical properties, including better adhesion, improved impact and vibration resistance

• Superior environmental resistance, including extreme temperatures, elimination of contamination, fogging and condensation in air gap